Processing Technology:

Green Anode Processing Technology

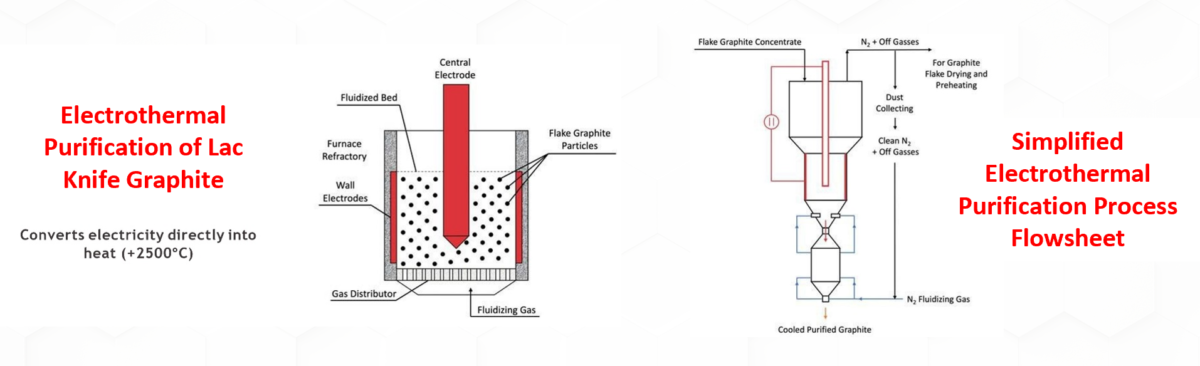

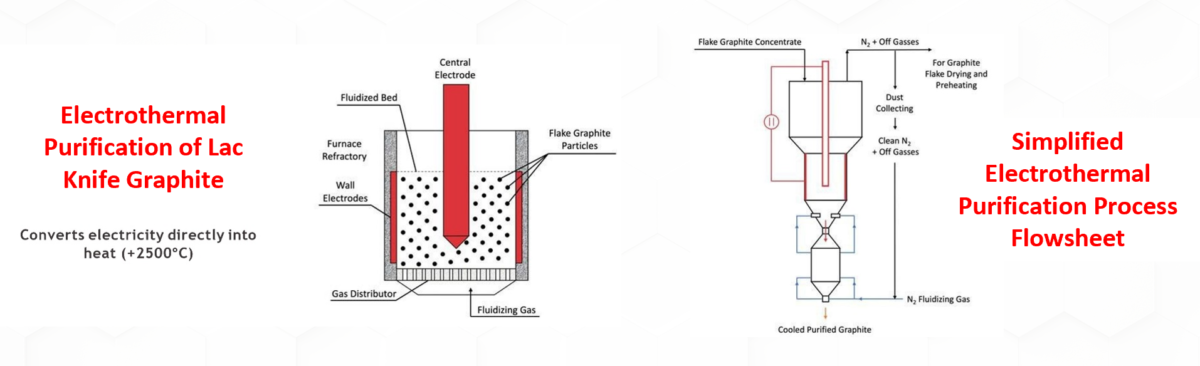

Eco-Friendly Purification Process

High heat removes impurities concentrated on the graphite’s surface, optimizing yield and purity.

This step is made possible by Lac Knife’s unique deposit, where impurities are located on the outside of the flake, allowing easy and efficient removal.

No harmful chemicals are used during processing.

In the end, the by-product is gypsum, repurposed for construction applications (e.g., drywall).

Alignment with Sustainability

Green processing technology aligns with Focus Graphite’s commitment to reducing environmental impact while producing premium-quality graphite materials.

Focus Graphite is committed to the greenest, most sustainable mining and processing practices, continuously partnering with institutions and industry to drive innovation.

Mining Technology:

Flake Characterization Study

The flake characterization study employs cutting-edge imaging techniques to analyze the distribution, size, and purity of graphite flakes directly from drill core and to integrate such information into the resource model.

The study focuses on:

- High-Resolution Optical Imaging and Image Processing: Core cuttings are mapped for in-situ distribution of jumbo, large, medium, and small graphite flakes to enable incorporation of estimated flake value in individual resource block models, informing selective mining strategies.

- Advanced Analytical Tools: The study utilizes the ARTSection automated correlative microscopy platform developed by IOS Geosciences, integrating different types of images including circular polarization, phase contrast, and back-scattered electron images. These images are segmented using AI-based algorithms to individualize flakes and provide textural quantification through routine, low-cost analyses.

- Flake Size Calibration: A series of grinding and beneficiation tests are being conducted. Concentrates will be analyzed for Carbon Content and Purity through Thermogravimetric Analysis (TGA) to refine downstream processing approaches.

- Environmental Characterization: The study will identify the abundance and textures of environmentally deleterious minerals, and tests will be conducted for sulfide recovery. By targeting high-purity zones and avoiding unnecessary disruption of non-graphitic material, the company aims to reduce waste and minimize its environmental footprint.

- Pilot-Scale Testing: Preliminary extractions will validate the feasibility of processing high-purity graphite at an industrial scale, ensuring optimized yield and efficiency.

Strategic & Environmental Benefits of the Study

- Improve the accuracy of the block model, enabling lower cut-off grades.

- Enhance efficiency of graphite extraction and processing, reducing operational costs and environmental impact.

- Strengthen Focus Graphite Advanced Materials’ position as a provider of premium, high-grade graphite tailored for niche applications such as energy storage, aerospace, and defense.

- Support sustainable resource development and responsible stewardship of high-purity flake graphite.

- Demonstrate the Company’s commitment to technological advancements in mineral exploration and processing.

Focus Graphite is committed to the greenest, most sustainable mining and processing practices, continuously partnering with institutions and industry to drive innovation.