North American Carbon Materials

Innovation Through Collaboration

Key Features of Our Materials and Process

- High-purity North American natural flake graphite.

- Complete chain-of-custody materials to ensure transparency and traceability.

- Environmentally sustainable processing methods.

- Advanced carbon materials designed for next-generation technological advancements.

Collaboration Opportunities

Industry Partnerships

- Collaborate with companies interested in testing or adopting advanced battery technologies, including our proprietary battery anode technology.

- Partner with organizations looking to leverage our materials and technologies for innovative applications.

- Work with businesses aiming to enhance their products with our green processing methods and advanced carbon materials.

ITB (Industrial and Technological Benefits) Opportunities

- Actively seeking partnerships with companies to collaborate on projects within National Defence and other critical sectors.

- Utilize our materials and technologies to support ITB-driven initiatives.

- Engage with companies to co-develop solutions using our high-purity graphite and green technologies.

Academic and Research Collaboration

- Partner with universities, academia, and researchers to advance material science and green technologies.

- Explore co-patenting opportunities for innovations developed collaboratively.

Grants and Global Partnerships

- Open to pursuing grants globally to drive innovation in green technologies, battery anode technology, and next-generation applications of our materials.

- Willing to collaborate with others on grant applications where leveraging our sustainable technologies, proprietary processes, or graphite deposit makes sense.

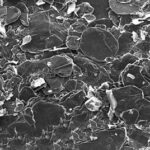

+50 Mesh

(Coarse Flake)

Applications:

- Expandable graphite

(used in batteries, fire

suppressants, and foils). - Ductile iron components.

- Fuel cells.

- Advanced metallurgical uses.

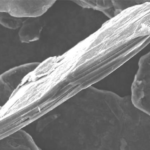

+80 to +100 Mesh

(Medium Flake)

Applications:

- Synthetic diamonds for

cutting tools, drill bits. - Ballistic armor.

- Graphite electrodes for smelting.

- Nuclear applications

(critical material for reactors).

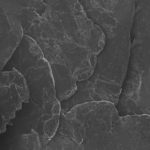

-100 to -400 Mesh

(Fine and Superfine Flake)

Applications:

- Battery materials (lithium-ion, lead-acid, and super capacitors).

- Stealth and radar suppression.

- Heat Resistant conductive

coatings. - Recycled graphite solutions.

- Anti-corrosion coatings.

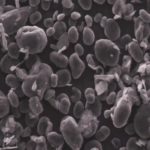

Sub -400 Mesh

(Ultra-Fine Flake)

Applications:

- Ballistic armor.

- Icephobic and conductive coatings.

- Additive steel making processes.

Supplying Innovative Technological Applications with High-Purity Natural Flake Graphite

Our Materials are Custom Engineered or Various Manufacturing Industries

Advanced Prototyping and Testing

We collaborate with the Advanced Energy Technologies Company (AETC) to validate our materials for high-end applications. The U.S. Navy and Army utilize AETC to validate materials for their various applications and strategic importance for the U.S.

Don’t let your competition leap ahead. Prototype and test our advanced carbon materials today to enhance your products and ensure a competitive edge. Explore the listed benefits and contact us to uncover additional opportunities specific to your needs.

The Power of North American Graphite Independence

With a North American deposit and a dedicated laboratory/manufacturing partner in North America, we can domestically prototype and test materials collaboratively. This results in highly customized solutions with a faster deployment to help you outperform competitors and improve product performance.

DOMESTIC SUPPLY CHAIN

- Located in North America.

- Mining-Friendly jurisdiction.

- Direct ground access.

- US & Canadian incentives, including grants, subsidies and tax.

HIGH VALUE PRODUCTS

- High-purity natural flake graphite.

- Multi-grade deposit for a wider range of applications.

LOW ENVIRONMENTAL IMPACT

- Unique deposit characteristics

allow for green processing. - No harmful chemicals in process.

- Gypsum is the benign byproduct of the entire process. This repurposing supports the circular economy.

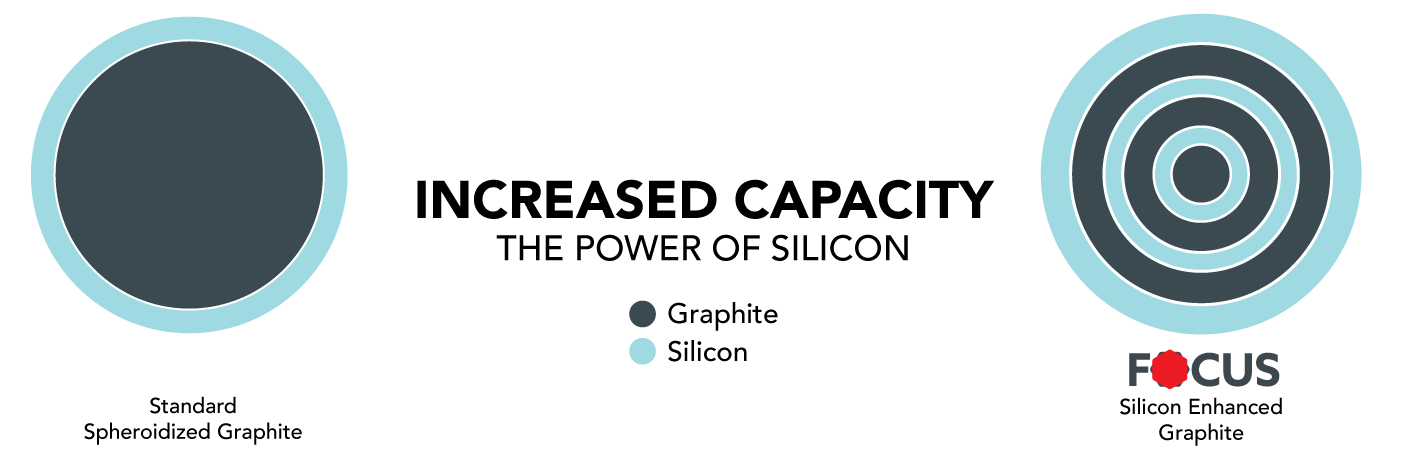

Patent-pending silicon-enhanced spheroidized anode technology

A Transformative Solution for EVs and Energy Systems.

We have developed a patent-pending silicon-enhanced spheroidized anode technology that significantly increases power and capacity in lithium-ion batteries. Successfully tested in coin cells, this innovation:

- Incorporates multiple layers of silicon during the spheroidization

phase of creating anodes resulting in enhanced performance. - Offers a major improvement over traditional anode technologies.

If you are interested in exploring grant opportunities or partnerships, please contact

We work on a case-by-case basis, offering tailored solutions and opportunities for joint intellectual property (IP) development.